Lưới che chắn

May 12,2023

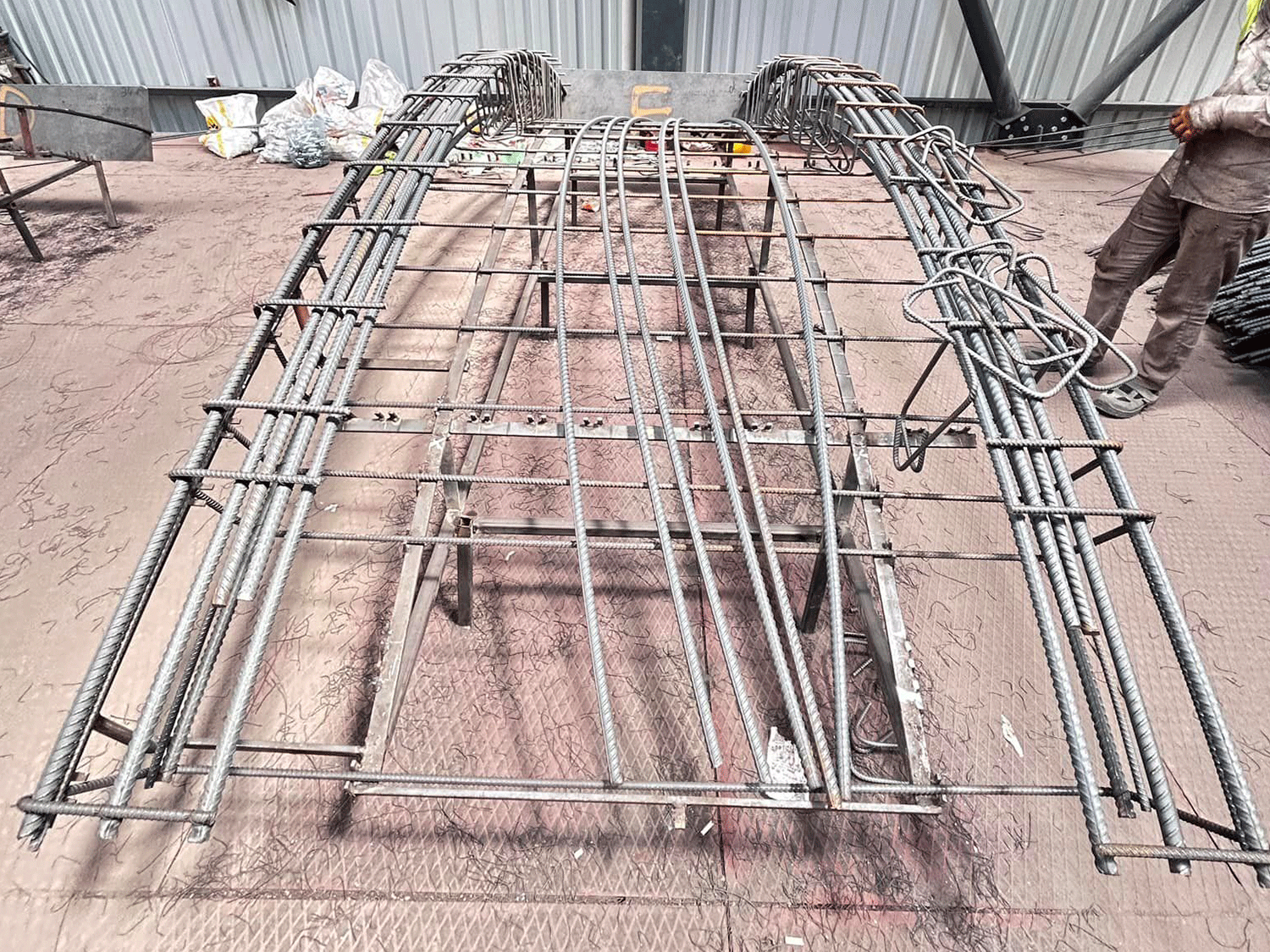

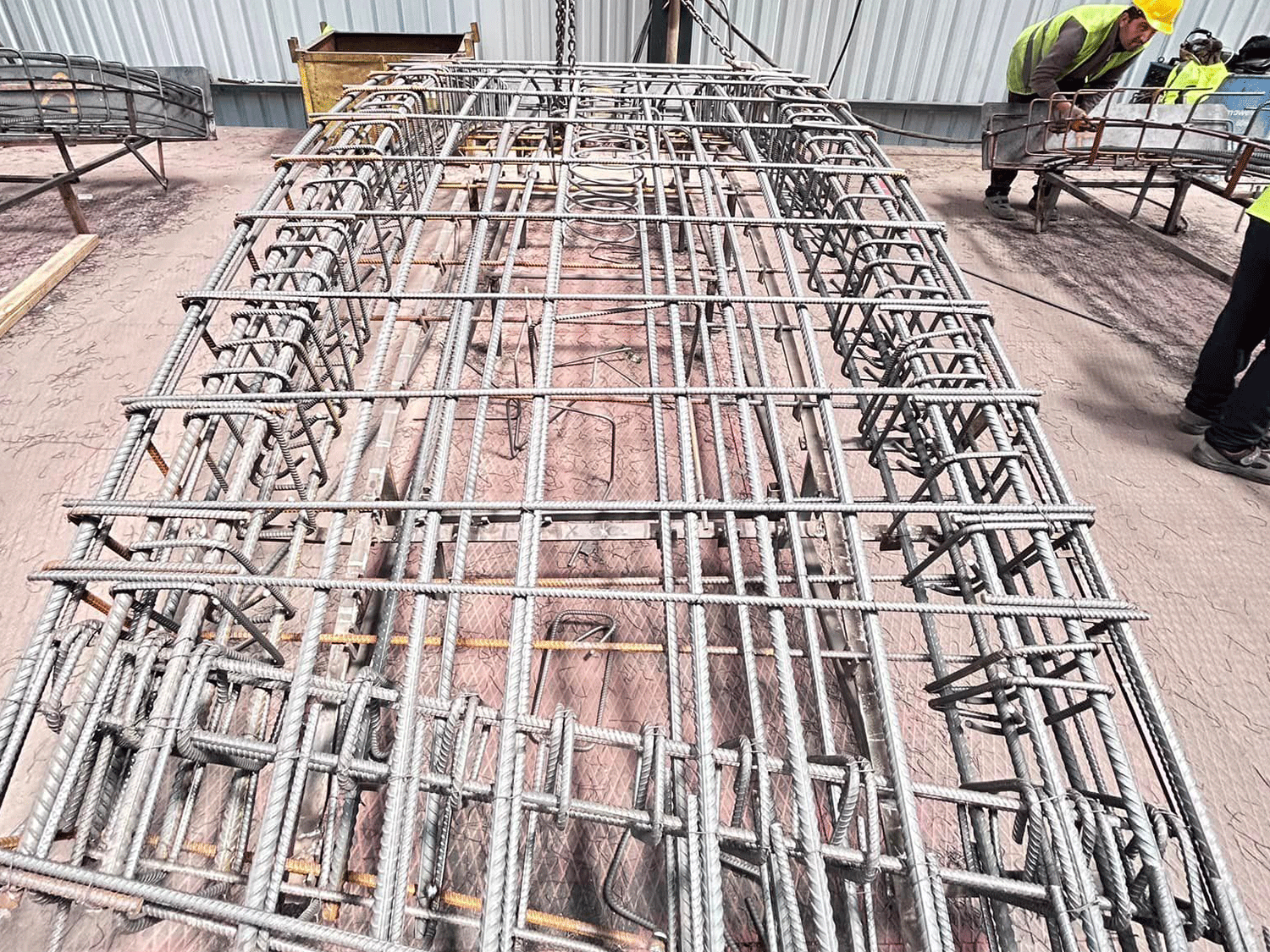

Shield tunnel segments are a sturdy composite production material for tunnel construction. The main processing difficulty of its internal steel reinforcement framework lies in the completion of fixed length cutting, bending and arc forming of large diameter steel bars, as well as the three-dimensional welding of multi-layer mesh combinations. For a long time, the production of shield tunnel segment reinforcement cages can only be processed into single bars using CNC equipment and then formed by manual binding and welding.

Question NO.1

The design is not conducive to mechanized production, and there are differences in the design source of the segment reinforcement cage, and the structure is relatively trivial.

Question NO.2

Production relies on manual labor and has a low level of automation, as the main processing difficulty of its internal steel reinforcement framework lies in completing the fixed length bending of large-diameter steel bars and achieving three-dimensional welding of multi-layer mesh combinations. Due to the lack of domestic machinery and technology, the long-term manual production mode has low production efficiency, poor safety, high labor intensity, and the continuous increase in labor costs, Traditional manual labor processing can no longer meet the needs of modern architecture.

Question NO.3

The difficulty of quality control standards for finished products is high, and in China, manual binding or welding can only be used, resulting in low work efficiency and forced relaxation of quality standards. Due to its low production efficiency, poor safety, high labor intensity, and the continuous increase in labor costs, traditional manual labor processing of steel bars can no longer meet the needs of modern architecture.

Ngày trước

Tiếp theo

Ngày trước

Tiếp theo

Trường hợp/Dịch vụ liên quan

Related Cases